Rho UK Appointed Identification Number 1266 ISO 25E UT 150 200bar Oxygen Tanks Seamless Steel Cylinders

Batch management of cylinder products

Our company has the conditions to allow mass production of products, and in accordance with the requirements of mass management for product manufacturing, inspection and testing. The quality records and inspection reports of the products shall be filed in batches, and the certificates of the products in batches shall be issued. Quality records shall be traceable to primary materials, welding materials, key process parameters and operators.

According to the Regulations on Gas Cylinder Safety Supervision, the steel seal of gas cylinder manufacturing shall include the enterprise code of the gas cylinder manufacturing unit, which must be put on record in the manufacturing license approval agency.

The enterprise code must be printed before the cylinder leaves the factory, otherwise the inspection certificate cannot be issued.

Our company is a legally registered gas cylinder manufacturer in China, enterprise code :HS

Also known as UT cylinders, 25E cylinders, seamless cylinders, 25E 200bar cylinders, 25E 150bar cylinders

Whether the distribution transport vehicles and personnel have licenses, and whether the transport meets the requirements;

Check whether there is an inspection date, whether there is a steel seal and whether it is within the validity period;

Cylinders are a product and a responsibility. Only strict gas cylinder traceability can let you use at ease.

We are a factory specializing in the production of seamless cylinders, can supply oxygen cylinders, nitrogen cylinders, carbon dioxide cylinders and argon cylinders, various, can be used for medical equipment or household oxygen, if you need, please contact me.

Our company is a regular production enterprise registered in China administration for Industry and Commerce

Welcome your call or email, we will reply in time, wish us a happy cooperation.

Here, I look forward to hearing from you.

The requirement of seamless cylinder is guaranteed by the allowable stress in the wall thickness formula, that is, from the aspect of safety factor.

In terms of plasticity and toughness, for cylindrical materials, more important than static compressive strength is elongation and toughness, strong impact resistance, large plastic deformation performance, and can inhibit the propagation of cracks.

1. The plastic and toughness of the cylinder must be improved by proper material selection and heat treatment because of its high conventional strength and seldom failure when standing.

2. Interpretation of cylinder test results (ISO9809-1):

A) Check the pressure/time curve or the pressure/volume curve using water to determine the pressure at which the cylinder begins plastic deformation and the burst pressure;

B) Check for burst tear and its edge shape.

3, threaded end finish stem threaded end should have a 45° chamfer, 1 ~ 2mm(maximum) from the bottom of the reference surface A, there is a groove at the top.

The first thread shall be fully formed and shall show the maximum clearance (d1I shall be the minimum clearance).

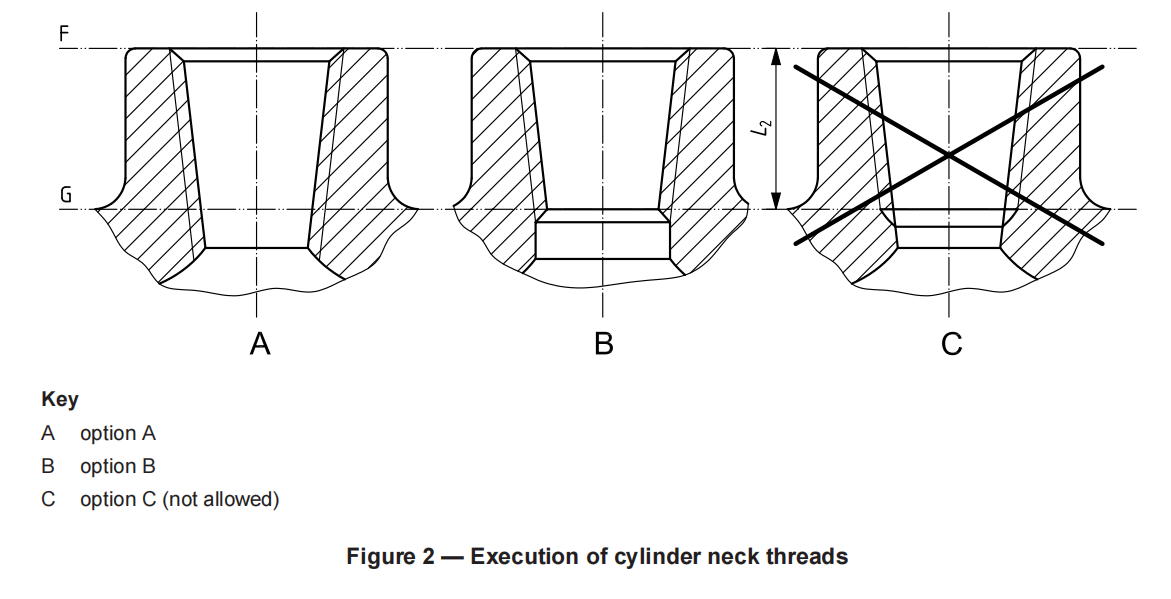

The cylinder neck thread shall have a 45° chamfering opening, 1 mm to 2 mm maximum from the plane

Neck threads should be executed as shown in Figure 2.

4、ISO9809-3 25E UT 150 bar Oxygen Tanks Seamless Steel Cylinders

We have manufacturing assurance capability of product safety performance

(1) Have the ability to independently complete the manufacture of gas cylinders and ensure product safety performance to ensure that product safety performance meets the requirements of safe use;

(2) The safety performance of our gas cylinder products shall meet the requirements of The Regulations on The Safety and Technical Supervision of Gas Cylinders, relevant safety technical specifications and relevant product standards. Where gas cylinders are manufactured using standards other than the coordinated standards, adoption standards, design documents and application materials that meet the safety performance of gas cylinders not lower than the prescribed requirements shall be provided.

(3) Our gas cylinder products contain process instructions (work instructions) and inspection procedures for all manufacturing processes of the licensed product.

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WMⅡ89-1L-150 | 89 | 1 | 240 | 1.83 | 150 | 2.4 | 37MN |

| WMⅡ89-1.4L-150 | 1.4 | 310 | 2.30 | ||||

WMⅡ108-2.0L-150 | 108 | 2 | 310 | 3.62 | 2.9 | ||

WMⅡ108-2.5L-150 | 2.5 | 374 | 4.29 | ||||

| WMⅡ108-3.0L-150 | 3.0 | 440 | 4.96 | ||||

| WMⅡ108-5.0L-150 | 5.0 | 696 | 7.74 | ||||

| WMⅡ140-3.4L-150 | 140 | 3.4 | 324 | 5.3 | 3.8 | ||

WMⅡ140-4.0L-150 | 4.0 | 375 | 5.89 | ||||

WMⅡ140-5.0L-150 | 5.0 | 447 | 6.96 | ||||

WMⅡ140-6.3L-150 | 6.3 | 540 | 7.88 | ||||

WMⅡ140-6.7-150 | 6.7 | 569 | 8.30 | ||||

WMⅡ140-8.0L-150 | 8.0 | 665 | 9.68 | ||||

| WMⅡ140-9.0L-150 | 9.0 | 744 | 10.7 | ||||

WMⅡ140-10.0L-150 | 10.0 | 818 | 11.9 | ||||

WMⅡ159-8.0L-150 | 159 | 8.0 | 548 | 9.11 | 4.3 | ||

| WMⅡ159-10.0L-150 | 10.0 | 660 | 10.9 | ||||

| WMⅡ159-12.0L-150 | 12.0 | 780 | 13.1 | ||||

| WMⅡ159-13.4L-150 | 13.4 | 861 | 15.4 | ||||

| WMⅡ159-15.0L-150 | 15.0 | 932 | 16.8 | ||||

| WMⅡ180-20.0L-150 | 180 | 20.0 | 1012 | 24.8 | 4.9 | ||

| ISO219-40.0L-150 | 219 | 40.0 | 1300 | 48.0 | 5.7 | ||

| ISO232-40.0L-150 | 232 | 40.0 | 1167 | 43.0 | 6.0 | ||

| ISO232-46.7L-150 | 46.7 | 1345 | 48.9 | ||||

| ISO232-47.0L-150 | 47 | 1351 | 49.0 | ||||

| ISO232-50.0L-150 | 50.0 | 1450 | 57.7 |

5、200bar ISO9809-1 25E UT Seamless Steel Cylinders Oxygen Tanks

In the production process of our gas cylinders, there are pressure cycle test requirements in the product batch inspection items, and there are pressure cycle test devices. The upper limit of cycle pressure and the number of test devices match the product manufacturing range and batch manufacturing capacity.

It shall have an air tightness test device matching the manufacturing capacity of the licensed product and supporting compressed gas continuous gas supply device, as well as necessary safety protection facilities;

In strict compliance with the blasting test requirements for bulk inspection of gas cylinder products, there are hydraulic blasting test devices suitable for product blasting pressure and capable of automatically recording pressure-water intake, pressure-time and water-input-time curves.

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WGⅡ89-1L-200 | 89 | 1 | 240 | 1.83 | 200 | 2.0 | 34CrMo4 |

| WGⅡ89-1.4L-200 | 1.4 | 310 | 2.30 | 2.0 | |||

WGⅡ108-2.0L-200 | 108 | 2 | 310 | 3.62 | 2.4 | ||

WGⅡ108-2.5L-200 | 2.5 | 374 | 4.29 | 2.4 | |||

| WGⅡ108-3.0L-200 | 3.0 | 440 | 4.96 | 2.4 | |||

| WGⅡ108-5.0L-200 | 5.0 | 696 | 7.74 | 2.4 | |||

| WGⅡ140-3.4L-200 | 140 | 3.4 | 324 | 5.3 | 3.1 | ||

WGⅡ140-4.0L-200 | 4.0 | 375 | 5.89 | 3.1 | |||

WGⅡ140-5.0L-200 | 5.0 | 447 | 6.96 | 3.1 | |||

WGⅡ140-6.3L-200 | 6.3 | 540 | 7.88 | 3.1 | |||

WGⅡ140-6.7-200 | 6.7 | 569 | 8.30 | 3.1 | |||

WGⅡ140-8.0L-200 | 8.0 | 665 | 9.68 | 3.1 | |||

| WGⅡ140-9.0L-200 | 9.0 | 744 | 10.7 | 3.1 | |||

WGⅡ140-10.0L-200 | 10.0 | 818 | 11.9 | 3.1 | |||

WGⅡ159-8.0L-200 | 159 | 8.0 | 548 | 9.11 | 3.5 | ||

| WGⅡ159-10.0L-200 | 10.0 | 660 | 10.9 | 3.5 | |||

| WGⅡ159-12.0L-200 | 12.0 | 780 | 13.1 | 3.5 | |||

| WGⅡ159-13.4L-200 | 13.4 | 861 | 15.4 | 3.5 | |||

| WGⅡ159-15.0L-200 | 15.0 | 932 | 16.8 | 3.5 | |||

| WGⅡ165-10.0L-200 | 165 | 10.0 | 615 | 12.5 | 3.6 | ||

| WGⅡ165-12.0L-200 | 12.0 | 725 | 14.4 | 3.6 | |||

| WGⅡ165-15.0L-200 | 15.0 | 880 | 17.2 | 3.6 | |||

| WGⅡ180-20.0L-200 | 180 | 20.0 | 1012 | 24.8 | 3.9 | ||

| ISO219-40.0L-200 | 219 | 40.0 | 1300 | 48.0 | 5.7 | ||

| ISO232-40.0L-200 | 232 | 40.0 | 1167 | 43.0 | 6.0 | ||

| ISO232-46.7L-200 | 46.7 | 1345 | 48.9 | 6.0 | |||

| ISO232-47.0L-200 | 47 | 1351 | 49.0 | 6.0 | |||

| ISO232-50.0L-200 | 50.0 | 1450 | 57.7 | 6.0 |

6、The mechanical properties of gas cylinders are also required by materials. Therefore, the heat treatment is summarized in the relevant material provisions, and the provisions are more detailed, obviously shows the level of research and attention to the gas cylinder material.

1. ISO

In ISO 4705, the material used to manufacture seamless cylinders should not be boiling steel: the chemical composition should not exceed the following limits: S and P -- 0. 04%, S+P -- 0.07%.

2. Japan

In JISB 8241 -- 1976, there are five kinds of cylinder materials: carbon steel, manganese steel, chromium-molybdenum steel, other alloy steel and stainless steel. Other alloy steels refer to manganese-molybdenum steel, nickel-chromium-molybdenum steel and other alloy steels. If the alloy element content above the following requirements, except manganese steel, chromium-molybdenum steel, in JISB 8241 are treated as alloy steel:

Si 0.60% Mo 0.05%