7L 200bar CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder

During the use of gas cylinders, the residual pressure of more than 0.05MPa should be left after use.

Combustible gas should be left 0.2mpa to 0.3mpa. H2 should be kept 2MPa in case of danger when it is re-inflated and cannot be used up.

Iso9809-1 production standard; 7 litre cylinder; 140mm cylinder outer diameter; 34CrMo4 alloy steel; Working pressure is 200bar; Hydrostatic test pressure is 300bar; TPED

All cylinders must undergo regular technical inspection.

Gas cylinders filled with general gas shall be inspected once every three years; If serious corrosion or damage is found in use, it shall be inspected in advance.

The height of the 7-litre argon gas bottle is 591mm; Cylinder mouth thread PZ27.8,PZ39; 25E; 3/4-14 NGT, etc.;

Maximum gas storage is 1.4m3 (1400 litres);

The minimum design wall thickness of the cylinder is 3.1mm; The weight of the 7-litre cylinder is 8.63kg;

Alias:7L 200bar cylinders; 7L 200bar gas tanks,200bar Argon cylinders,TPED Helium gas tanks,200bar Air gas cylinders; 7litre 200bar gas cylinders; 7litre 200bar gas bottles; 7litre 200bar gas tanks;

Made in china

7L 200bar ISO9809-1 CO2 cylinder Argon nitrogen helium N2O cylinder

Manufacture of cylinders - the main material of cylinders

First, the main material of the gas cylinder

Reasonable selection of materials is the prerequisite to ensure the quality of gas cylinders.

Basic requirements for cylinder body materials

1. Have enough strength, especially high pressure cylinders should have high strength and appropriate flexion strengthening, in order to reduce the weight of cylinders, and give full play to the potential of materials;

2. Having certain plasticity and toughness; And has good low temperature performance, to adapt to the characteristics of large flow of gas cylinders and complex use environment:

3. The material is more stable and uniform; Good anti-fatigue performance, can ensure the fatigue life of the whole service period;

4. Good corrosion resistance;

5. Easy to manufacture and processing, high pressure cylinders should have good malleability, low pressure welding cylinders should have good weldability;

General requirements knowledge points

1、Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

2、Products can be exported to countries or regions:China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

3、Minimum order quantity: 100 only

4、Common nonconformance points in gas bottles production :

— Manufacturing imperfections of gas bottles:

a/Excessive grinding or machining: Local reduction of wall thickness by grinding or machining

This is not allowed when the cylinder wall thickness is reduced below the minimum design thickness

Often seen in refurbished cylinders, with expired cylinders, the stencil erased, re-stencil.

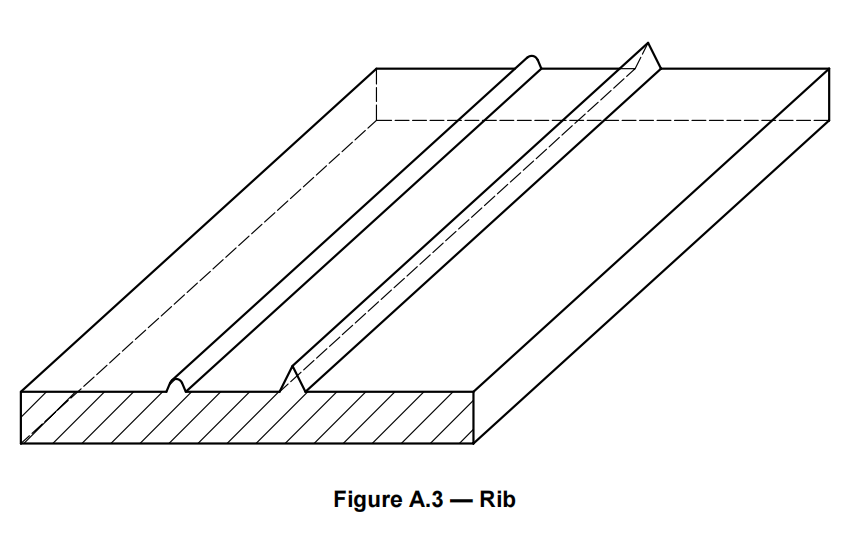

b/Rib :A longitudinal raised surface with sharp corners having a height of 3% or more than the wall thickness (see Figure A.3)

⎯ Inside imperfection: when height exceeds 5 % of wall thickness or when length exceeds 10 % of the length of the cylinders

⎯ Outside imperfection: when height exceeds 5 % of wall thickness or when length exceeds 5 times the thickness of the cylinders.

5、7 litre Gas Cylinder Product Parameters table (ISO9809-1 TPED 200bar)

7L 200bar CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WGⅡ140-7.0L-200 | 140 | 7.0 | 591 | 8.63 | 200 | 3.1 | 34CrMo4 |