20L 150bar CO2 Bottle Argon Nitrogen Helium N2O Air Cylinder

20L 150bar CO2 bottle Argon Nitrogen Helium N2O Air cylinder

In case of cylinder faults in use, such as serious valve leakage or valve switch failure, the handwheel switch of the cylinder valve should be turned to the closed position, and then sent to the gas filling unit or professional cylinder inspection unit for treatment.

Personnel without professional training and without understanding the structure and repair method of the bottle valve shall not repair;

20 litre industrial oxygen cylinders; 37 mn manganese steel; Industrial oxygen cylinder production standard GB/T5099.3 or ISO9809-3; TUV; The outer diameter of oxygen tank is 159mm; Oxygen tank working pressure is 150bar; The hydrostatic test pressure of oxygen tank is 250bar;

It is strictly forbidden to change the steel seal and color mark of gas cylinder without authorization;

20 litre industrial oxygen cylinder height 1012mm; 20 liter gas cylinder body weight 24.8KG; The 20 litre cylinder has a maximum storage capacity of 3m3 (3000 litres); Cylinder mouth thread PZ27.8; 25E; 3/4-14 NGT, etc.; The minimum design wall thickness of the cylinder is 4.9mm;

Cylinders: gas cylinders, gas bottles, 20L gas cylinders, TUV N2O gascylinder, 150bar Argon bottles;20 litre gas bottles; 20 litre gas cylinder; 20 litre gas tanks

20L 150bar CO2 Bottle Argon Nitrogen Helium N2O Air Cylinder

1、Minimum order quantity: 100 only

2、Use cylinders:Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

3、Products can be exported to countries or regions:China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

4、Factory (we are the manufacturer):Shandong Hongsheng Pressure Vessel Co., LTD

5、 Impact test of gas cylinders:

Except for the requirements set out in this subclause, the test shall be carried out in accordance with ISO 148-1.

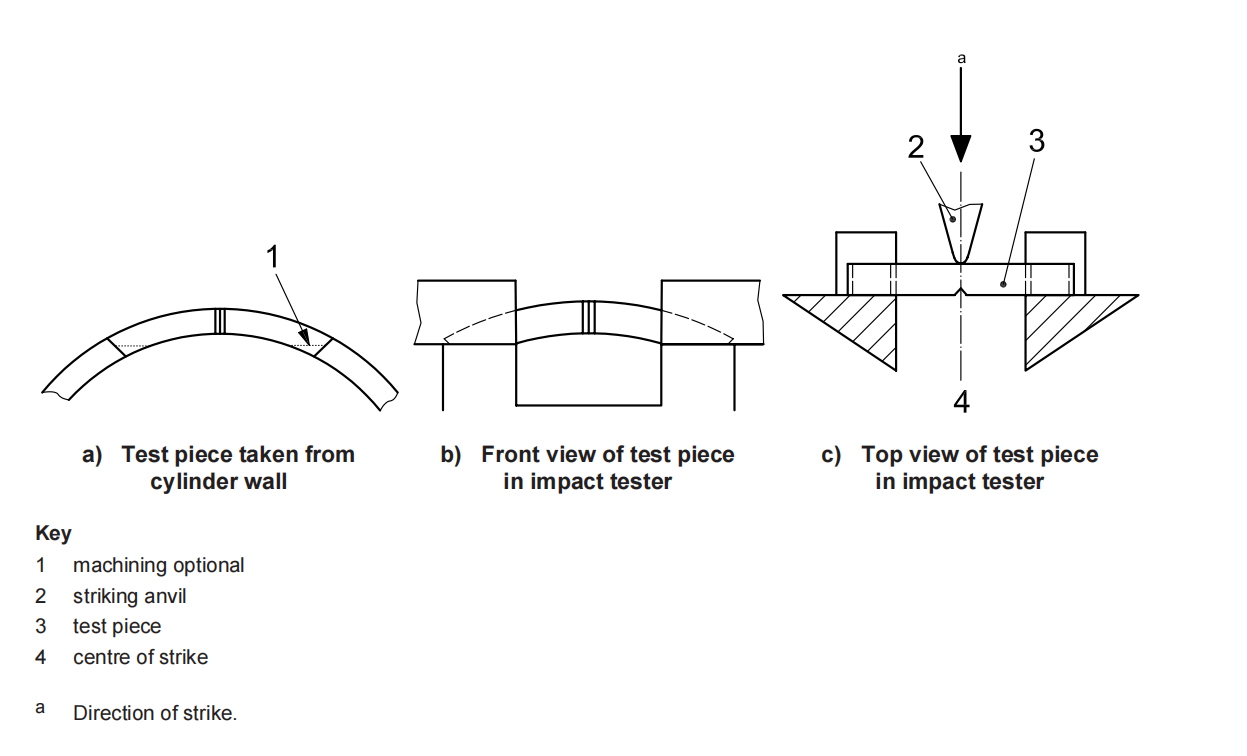

The impact test pieces shall be taken in the direction as required from the wall of the cylinder.

The notch shall be perpendicular to the face of the cylinder wall .

For longitudinal tests, the test piece shall be machined all over . If the wall thickness does not permit a final test piece width of 10 mm, the width shall be as near as practicable to the nominal thickness of the cylinder wall.

The test pieces taken in the transverse direction shall be machined on four faces only, the outer face of the cylinder wall being unmachined and the inner face optionally machined as shown in Figure

6、20 litre Gas Cylinder Product Parameters table (ISO9809-3)

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WMAⅡ180-20.0L-150 | 180 | 20.0 | 1012 | 24.8 | 150 | 4.4 | 37MN |