UK Market 1266 ISO 150bar 37MN TUV Oxygen Tanks Gas Bottle Industrial Cylinders

ISO 150bar 37MN Oxygen tanks gas bottle industrial cylinders

Shandong Hongsheng pressure Vessel Co., Ltd. is not only a gas cylinder supplier, but also your long-term comprehensive partner.

Our business philosophy: integrity-based, customer first.

The cylinder shall remain in one piece and shall not fragment.

The main fracture shall be in the cylindrical portion and shall not be brittle, i.e. the fracture edges shall be inclined with respect to the wall.

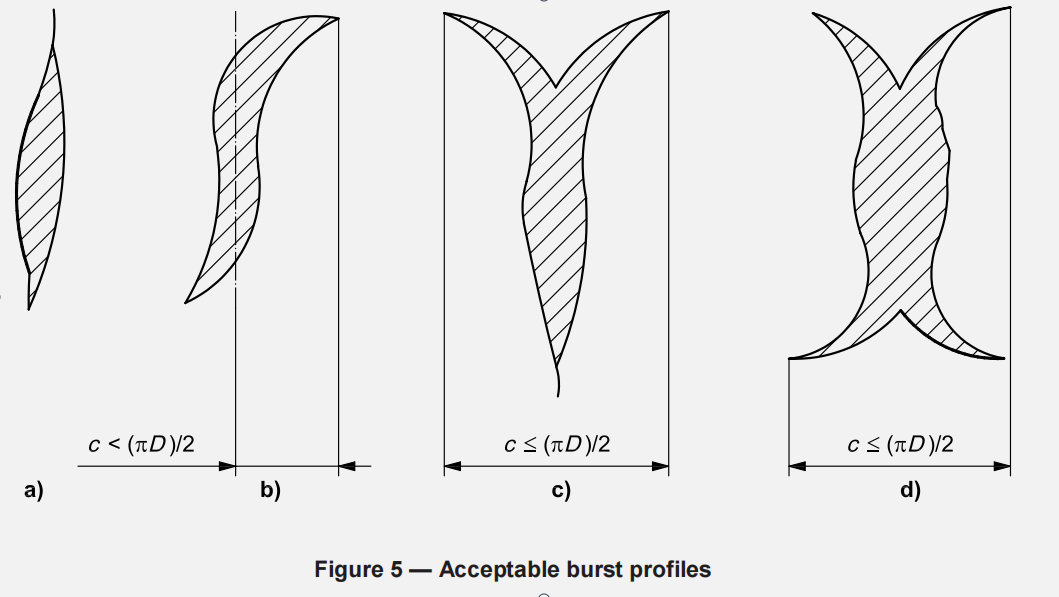

The tear shall not reveal a significant imperfection in the metal and in no case shall reach the neck.

For concave bases, the tear shall not run further than the cylindrical body at the base end and for convex bases, the tear shall not reach the centre of the base.

150bar 37MN ISO9809-3 Oxygen Tanks Gas Bottle Industrial Cylinders

1、Minimum order quantity: 100 only

2、We are China's gas cylinder production factory, product sales:China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

3、Use gas cylinders:Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

4、We require that the appearance of the bottom of the bottle should be smooth, without folding, steps and grooves. The inner surface of the bottom of the bottle should not have visible concave holes, folds, bumps and oxide skin; The outer diameter and height of the bottle mouth should meet relevant standards (such as ISO9809-3/ISO9809-1/GB/T5099.3/TUV/TPED);

5、EN ISO 11114-4, Transportable gas cylinders — Compatibility of cylinder and valve materials with gas contents — Part 4: Test methods for selecting metallic materials resistant to hydrogen embrittlement EN ISO 13769, Gas cylinders — Stamp marking.

6、For cylinders with a wall thickness of less than 7,5 mm, the fracture shall be acceptable only if it conforms to one of the following descriptions: ⎯ longitudinal, without branching [see Figure 5 a)]; ⎯ longitudinal, with a side branching at each end, which in no case extends beyond the longitudinal plane normal to the fracture plane [see Figure 5 b)]; ⎯ longitudinal, with fishtail branching at one end [see Figure 5 c)], or at both ends [see Figure 5 d)].

Product Information:

1、Iso9809-3 or GB/T5099.3 production standards; 0.8 liters to 80 liters; 89mm-267mm cylinder outer diameter; Working pressure is 150bar; 37 mn material; Hydrostatic test pressure is 250bar;

2、Cylinder mouth threads include PZ19.2,PZ27.8,PZ39; 25E; 3/4-14 NGT, etc.; Maximum gas storage is 0.12m3-12m3 (150L-12000L); The cylinder body weight is 1.60kg-72.4kg; The height of the cylinder body is 197mm-1520mm; The minimum design wall thickness of gas cylinders is 2.4mm-6.2mm;

3、Aliases:150bar Oxygen Tanks; 37 mn Oxygen tanks. 150 bar gas bottle; Industrial Oxygen cylinders; Industrial Oxygen tanks

4、Type approval procedure :A technical specification of each new design of cylinders or cylinder family as defined in , including design drawing, design calculations, steel details, manufacturing processes and heat treatment details, shall be submitted by the manufacturer to the inspector. The type approval tests detailed in shall be carried out on each new design under the supervision of the inspector.

5、A cylinder shall be considered to be of a new design, compared with an existing approved design, when at least one of the following applies:

a) it is manufactured in a different factory;

b) it is manufactured by a different process ; this includes the case when major process changes are made during the production period, e.g. end forging to spinning, change in type of heat treatment etc.;

6、The cylinder bases shall be sectioned to measure the thickness and to ensure that this thickness is sufficiently close to the minimum thickness prescribed in the design and shall be within the usual production tolerances. In no case shall the actual base thickness exceed the minimum value(s) specified on the drawing by more than 15 %.

Shandong Hongsheng Pressure Vessel Co., Ltd. is willing to be your long-term partner and chief cylinder safety officer, and jointly escort your cylinder safety.

7、Product parameters table(ISO9809-3)

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WMAⅡ89-1L-150 | 89 | 1 | 240 | 1.83 | 150 | 2.4 | 37MN |

| WMAⅡ89-1.4L-150 | 89 | 1.4 | 310 | 2.30 | 150 | 2.4 | 37MN |

WMAⅡ108-2.0L-150 | 108 | 2 | 310 | 3.62 | 150 | 2.9 | 37MN |

WMAⅡ108-2.5L-150 | 108 | 2.5 | 374 | 4.29 | 150 | 2.9 | 37MN |

| WMAⅡ108-3.0L-150 | 108 | 3.0 | 440 | 4.96 | 150 | 2.9 | 37MN |

| WMAⅡ108-5.0L-150 | 108 | 5.0 | 696 | 7.74 | 150 | 2.9 | 37MN |

| WMⅡ140-3.4L-150 | 140 | 3.4 | 324 | 5.3 | 150 | 3.8 | 37MN |

WMⅡ140-4.0L-150 | 140 | 4.0 | 375 | 5.89 | 150 | 3.8 | 37MN |

WMⅡ140-5.0L-150 | 140 | 5.0 | 447 | 6.96 | 150 | 3.8 | 37MN |

WMⅡ140-6.3L-150 | 140 | 6.3 | 540 | 7.88 | 150 | 3.8 | 37MN |

WMⅡ140-6.7-150 | 140 | 6.7 | 569 | 8.30 | 150 | 3.8 | 37MN |

WMⅡ140-8.0L-150 | 140 | 8.0 | 665 | 9.68 | 150 | 3.8 | 37MN |

| WMⅡ140-9.0L-150 | 140 | 9.0 | 744 | 10.7 | 150 | 3.8 | 37MN |

WMⅡ140-10.0L-150 | 140 | 10.0 | 818 | 11.9 | 150 | 3.8 | 37MN |

WMⅡ159-8.0L-150 | 159 | 8.0 | 548 | 9.11 | 150 | 4.3 | 37MN |

| WMⅡ159-10.0L-150 | 159 | 10.0 | 660 | 10.9 | 150 | 4.3 | 37MN |

| WMⅡ159-12.0L-150 | 159 | 12.0 | 780 | 13.1 | 150 | 4.3 | 37MN |

| WMⅡ159-13.4L-150 | 159 | 13.4 | 861 | 15.4 | 150 | 4.3 | 37MN |

| WMⅡ159-15.0L-150 | 159 | 15.0 | 932 | 16.8 | 150 | 4.3 | 37MN |

| WMⅡ180-20.0L-150 | 180 | 20.0 | 1012 | 24.8 | 150 | 4.9 | 37MN |

| ISO219-40.0L-150 | 219 | 40.0 | 1300 | 48.0 | 150 | 5.7 | 37MN |

| ISO232-40.0L-150 | 232 | 40.0 | 1167 | 43.0 | 150 | 6.0 | 37MN |

| ISO232-46.7L-150 | 232 | 46.7 | 1345 | 48.9 | 150 | 6.0 | 37MN |

| ISO232-47.0L-150 | 232 | 47 | 1351 | 49.0 | 150 | 6.0 | 37MN |

| ISO232-50.0L-150 | 232 | 50.0 | 1450 | 57.7 | 150 | 6.0 | 37MN |