4L 200bar CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder

2024-04-15 06:30

4L 200bar CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder

4L 200bar ISO9809-1 CO2 cylinder Argon nitrogen helium N2O cylinder

High-pressure gas cylinders must be kept in separate places and fixed securely when placed upright; Keep gas cylinders away from heat sources, avoid exposure and strong vibration.

34 crmo4. Hydrostatic test pressure is 300bar,TPED 4-litre oxygen tank; 108mm or 140mm cylinder outer diameter; The working pressure of the gas tank is 200bar; ISO9809-1 standard;

On the shoulder of the cylinder, the following marks shall be stamped: manufacturer, date of manufacture, cylinder model, working pressure, pneumatic test pressure, pneumatic test date and next delivery date, gas volume, cylinder weight

Cylinder mouth threads include PZ19.2,PZ27.8,25E; 3/4-14 NGT, etc.;

Maximum gas storage is 0.8m3 (800 litres); The height of the 4L 200AR cylinder body is 568mm or 375mm; The minimum design wall thickness of cylinders is 2.4mm or 3.1mm; The weight of the 4-litre cylinder is 6.3kg or 5.89kg;

Alias: 4L 200bar cylinders,4L 200bar Gas Tanks,Air Tanks,TPED Argon Gas Tanks,200bar Oxygen cylinders; 4litre 200bar gas cylinders; 4litre 200bar gas bottles; 4litre 200bar gas tanks;

Major diameter, d1e diameter of the major cone at the valve stem thread reference plane A (before any chamfer is cut)

1、Products exported :China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

2、Minimum order quantity: 100 only

3、Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

4、Common nonconformance points in gas cylinder production

-- Manufacturing celebrities of cylinders:

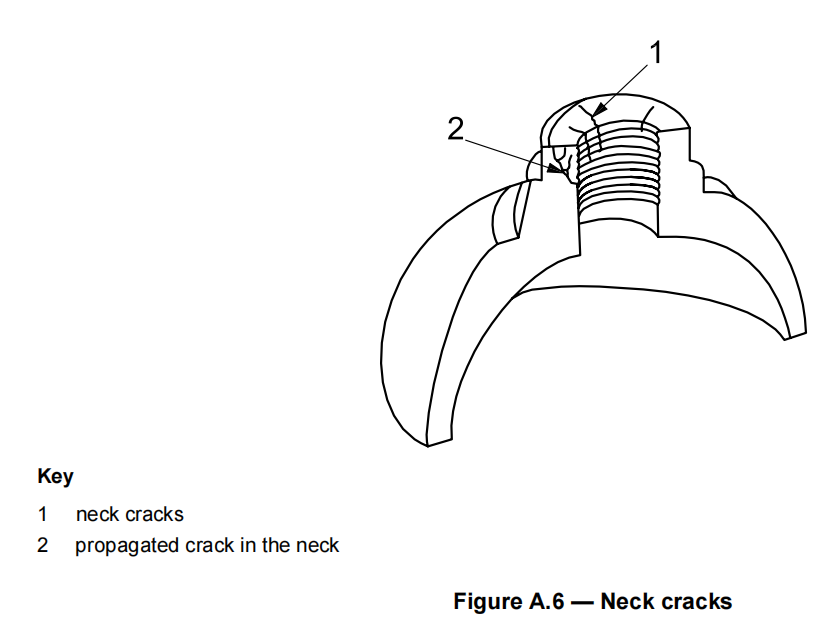

a/Neck cracks:Appear as lines which run vertically down the thread and across the thread faces (not to be confused with tap marks = thread machining marks; see Figure A.6)

5、Gas cylinder corrosion resistance

The influence of various elements in steel on corrosion resistance is as follows:

Carbon: generally, the lower the carbon, the less oxygen corrosion.

Manganese: manganese content (0.4 ~ 1.5%) in the case of high sulfur content, there will be manganese sulfide, which has an effect on corrosion, but in the case of low sulfur content, manganese and iron form a solid solution, which has no effect on corrosion.

Phosphorus: phosphorus content under 0.04%, can improve the corrosion resistance of steel in the atmosphere, especially when steel contains steel, corrosion resistance is more significant.

Sulfur: In the presence of manganese sulfide, as iron sulfide, there is an element of local battery formation, but little effect in neutral solution.

Copper: gas cylinder steel with copper content below 0.5% is solid solution, its corrosion resistance is very good, together with phosphorus, the effect is better.

Chromium: Molybdenum and chromium coexist, strong oxidation resistance, high corrosion resistance.

6、4 litre Gas Cylinder Product Parameters table

4L 200bar CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder(ISO9809-1 TPED 200BAR)

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WGⅡ108-4.0L-200 | 108 | 4.0 | 568 | 16.30 | 200 | 2.4 | 34CrMo4 |

| WGⅡ140-4.0L-200 | 140 | 4.0 | 375 | 5.89 | 200 | 3.1 | 34CrMo4 |