ISO9809-1 TUV TPED 200bar 34CrMo4 Oxygen Tanks Gas Cylinders

Product Information:

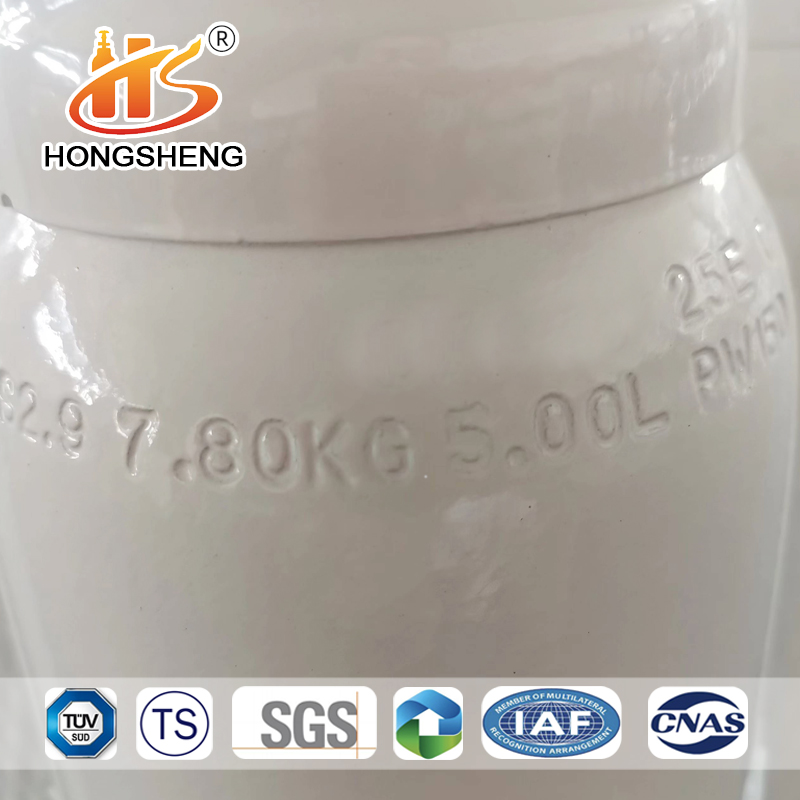

1、89mm-232mm cylinder outer diameter; 0.8 litres to 50 litres; Working pressure is 200bar; Hydrostatic test pressure is 300bar; 34 c4mo4 material; Iso9809-1 production standard;

2、Minimum design wall thickness of gas cylinders: 2.0mm-6.2mm; Height of cylinder body: 197mm-1520mm; Cylinder body weight: 1.60kg-72.4kg; Cylinder mouth threads include PZ19.2,PZ27.8,PZ39; 25E; 3/4-14 NGT, etc.; Maximum gas storage is 0.24m3-10m3 (300L-10000L)

3、Aliases: Iso9809-1 Gas cylinders; ISO9809-1 gas cylinders. 200 bar gas cylinders. 34 crmo4 gas cylinders. TPED gas tanks

ISO9809-1 TUV TPED 200bar 34CrMo4 Oxygen Tanks Gas Cylinders

1、Minimum order quantity: 100 only

2、Use cylinders:Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

3、We are China's gas cylinder production factory, product sales:China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

Tips for safe use of gas cylinders:

1、Material backfilling is the main cause of chemical explosion. In order to prevent backfilling, it is forbidden to use vacuum pump to extract gas from gas cylinders.

2、The gas in the cylinders should not be used up completely, and residual pressure should be left to prevent air or other substances from being inhaled. Gas cylinders with excess pressure are also convenient for filling units to carry out inspection.

3、Handling gas cylinders should be lightly loaded and unloaded. It is forbidden to roll, throw, reverse and other rough ways. It is forbidden to use electromagnetic cranes to carry gas cylinders in the factory.

Shandong Hongsheng Pressure Vessel Co., Ltd. is willing to be your long-term partner and chief cylinder safety officer, and jointly escort your cylinder safety.

4、Cylinder riveting neck processing process :

1). Riveting collar is a process in which the collar is fixed on the cylinder mouth by using the basic principle of cold rolling by riveting neck machine. Riveting neck machine is also called steel neck ring rolling riveting machine.

2.) Riveting collar is not easy to loosen the fixing bottle cap to ensure the integrity of the valve.

3). Riveted collar should ensure that the end face of the cylinder nozzle can not be destroyed to the thread, and the thread gauge can be successfully detected

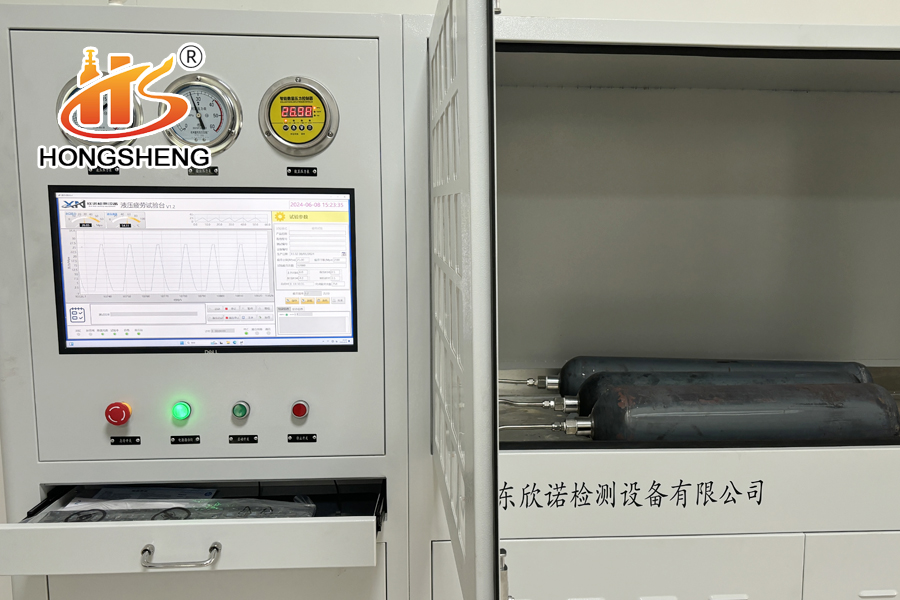

5、Heat treatment : The cylinder manufacturer shall certify the heat treatment process applied to the finished cylinders.

Quenching in media other than mineral oil is permissible provided that:

⎯ the method produces cylinders free of cracks.

⎯ the manufacturer ensures that the rate of cooling does not produce any cracks in the cylinder.

⎯ every production cylinder is subjected to a method of non-destructive testing to prove freedom from cracks, if the average rate of cooling in the medium is greater than 80 % of that in water at 20 °C without additives.

⎯ during the production of cylinders, the concentration of the quenchant is checked and recorded during every shift to ensure that the limits are maintained. Further documented checks shall be carried out to ensure that the chemical properties of the quenchant are not degraded.

6、Product parameters table(ISO9809-1 200bar gas cylinders)

Type | Outside Diameter (mm) | Water Capacity (L) | Bottle Height (mm) | Weight (kg) | Working pressure (Bar) | Design wall thickness (mm) | Material Grades |

| WGⅡ89-1L-200 | 89 | 1 | 240 | 1.83 | 200 | 2.0 | 34CrMo4 |

| WGⅡ89-1.4L-200 | 89 | 1.4 | 310 | 2.30 | 200 | 2.0 | 34CrMo4 |

WGⅡ108-2.0L-200 | 108 | 2 | 310 | 3.62 | 200 | 2.4 | 34CrMo4 |

WGⅡ108-2.5L-200 | 108 | 2.5 | 374 | 4.29 | 200 | 2.4 | 34CrMo4 |

| WGⅡ108-3.0L-200 | 108 | 3.0 | 440 | 4.96 | 200 | 2.4 | 34CrMo4 |

| WGⅡ108-5.0L-200 | 108 | 5.0 | 696 | 7.74 | 200 | 2.4 | 34CrMo4 |

| WGⅡ140-3.4L-200 | 140 | 3.4 | 324 | 5.3 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-4.0L-200 | 140 | 4.0 | 375 | 5.89 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-5.0L-200 | 140 | 5.0 | 447 | 6.96 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-6.3L-200 | 140 | 6.3 | 540 | 7.88 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-6.7-200 | 140 | 6.7 | 569 | 8.30 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-8.0L-200 | 140 | 8.0 | 665 | 9.68 | 200 | 3.1 | 34CrMo4 |

| WGⅡ140-9.0L-200 | 140 | 9.0 | 744 | 10.7 | 200 | 3.1 | 34CrMo4 |

WGⅡ140-10.0L-200 | 140 | 10.0 | 818 | 11.9 | 200 | 3.1 | 34CrMo4 |

WGⅡ159-8.0L-200 | 159 | 8.0 | 548 | 9.11 | 200 | 3.5 | 34CrMo4 |

| WGⅡ159-10.0L-200 | 159 | 10.0 | 660 | 10.9 | 200 | 3.5 | 34CrMo4 |

| WGⅡ159-12.0L-200 | 159 | 12.0 | 780 | 13.1 | 200 | 3.5 | 34CrMo4 |

| WGⅡ159-13.4L-200 | 159 | 13.4 | 861 | 15.4 | 200 | 3.5 | 34CrMo4 |

| WGⅡ159-15.0L-200 | 159 | 15.0 | 932 | 16.8 | 200 | 3.5 | 34CrMo4 |

| WGⅡ165-10.0L-200 | 165 | 10.0 | 615 | 12.5 | 200 | 3.6 | 34CrMo4 |

| WGⅡ165-12.0L-200 | 165 | 12.0 | 725 | 14.4 | 200 | 3.6 | 34CrMo4 |

| WGⅡ165-15.0L-200 | 165 | 15.0 | 880 | 17.2 | 200 | 3.6 | 34CrMo4 |

| WGⅡ180-20.0L-200 | 180 | 20.0 | 1012 | 24.8 | 200 | 3.9 | 34CrMo4 |

| ISO232-40.0L-200 | 232 | 40.0 | 1167 | 43.0 | 200 | 6.0 | 34CrMo4 |

| ISO232-46.7L-200 | 232 | 46.7 | 1345 | 48.9 | 200 | 6.0 | 34CrMo4 |

| ISO232-47.0L-200 | 232 | 47 | 1351 | 49.0 | 200 | 6.0 | 34CrMo4 |

| ISO232-50.0L-200 | 232 | 50.0 | 1450 | 57.7 | 200 | 6.0 | 34CrMo4 |